MIL-V-82443(OS)

4.4.1

Tests and examinations. The preproduction sample of 12

valves shall be inspected in accordance with Table IV, with 2 valves

being tested in accordance with each of the 6 test sequences, A through

F. In addition, the sample quantity of 25 squibs shall be subjected to

the tests detailed in 4.5.7 through 4.5.7.5.

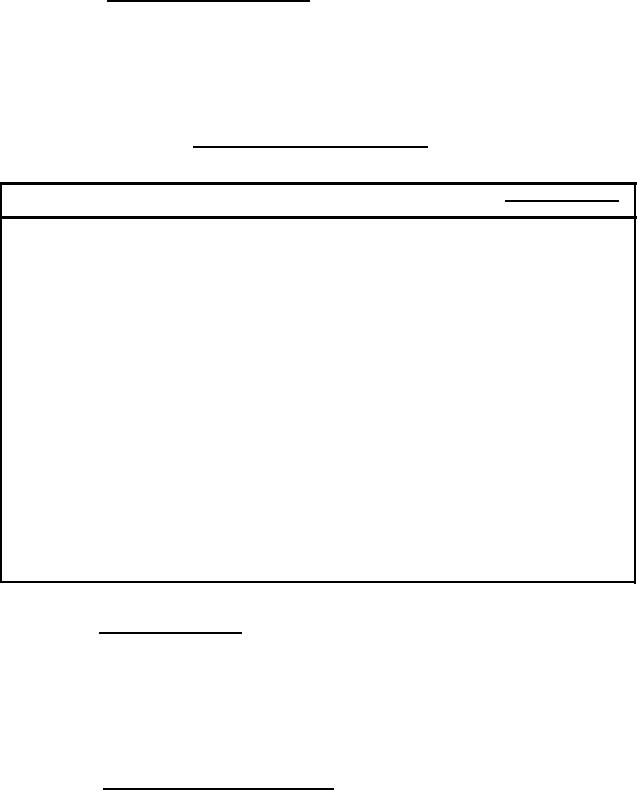

TABLE IV

PREPRODUCTION TEST SEQUENCE

Paragraph

Test Sequence

Tests

ABCDEF

Reference

4.4.4.1

111111

Inspection, Prior to Firing

4.4.4.2

2

2222

Auto-Ignition, Low Temperature

4.4.4.3

2

Auto-Ignition, High Temperature

Vibraiton, Ready Condition

4.4.4.4

3

Acceleration, Ready Condition

4.4.4.5

3

4.4.4.6

Shock, Ready Condition

3

4.4.4.7

44

Temperature and Humidity

4.4.4.8

Low Temperature Operating

5

4.4.4.9

5

High Temperature Operating

4.4.4.10

Vibration, Packed and Packaged

3

4.4.4.11

3

Shock, Packed and Packaged

4.4.4.12

4

No-Fire Current

4.4.4.13

5

44

Firing Current

4.4.4.14

6

6655

Visual Inspection, After Firing

4.4.4.15

7

7766

Ram Operation

Leakage at Operating Pressure, Normally

4.4.4.16

8

8877

Closed Outlet Port, After Firing

Leakage at Operating Pressure, Inlet and

4.4.4.17

9

9

9

8

8

Outlet Ports, After Firing

4.4.2

Test conditions. Unless otherwise specified, the valves shall

be subjected to the tests in 4.4.1 under the following conditions:

Temperature:

a.

Room ambient +32° F to +98° F

b.

Altitude:

Normal ground atmospheric pressure

c.

Vibration:

None

Humidity:

Room ambient

d.

4.4.3

Test equipment and set-up. In addition to the items listed

in 4.5.5, test equipment is required which provides the following

characteristics:

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business