MIL-V-82444A(OS)

4.4.4 Test procedures

4.4.4.1 Inspection. The valve shall be subjected to the inspections,

prior to firing, detailed in 4.5.6.1 through 4.5.6.4.

*

4.4.4.2 Auto-ignition, low temperature. The valve (or sample squib)

shall be heated in air to a temperature of +170° F ±2° F and maintained

at that temperature of 2 hours. The valve (or sample squib) shall not

fire. Thereafter, the valve (or sample squib) shall be capable of

meeting the requirements of 4.4.4.11.

4.4.4.3 Auto-ignition, high temperature. The valve shall be heated

O

in air to a temperature of +200° F ±10 F and maintained at. that

temperature for 8 hours. The valve shall not fire. Thereafter, the

valve shall not be required to meet the operating characteristics:

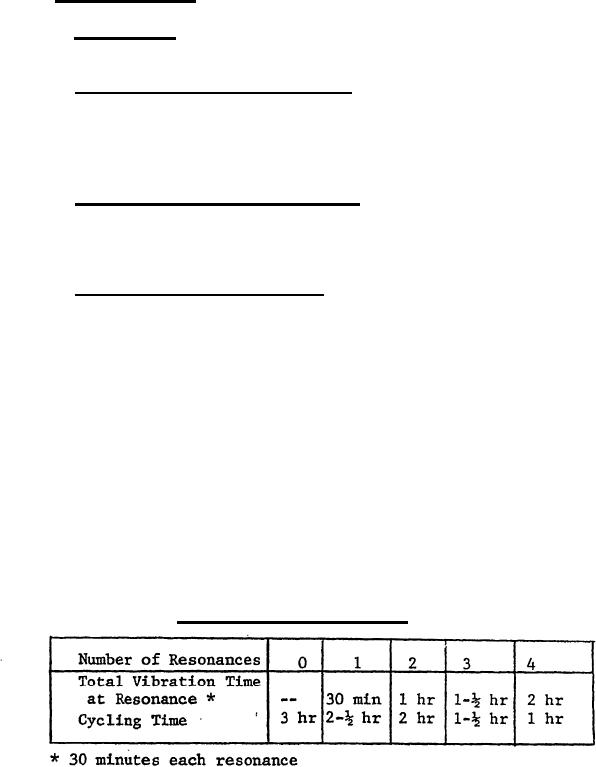

4,4.4.4 Vibration, ready condition. The valve, in the ready condition,

shall be mounted in a manner equivalent to that shown in Figure 1. The

resonant modes in each of the 3 axes shall be determined by varying the

frequency of applied vibration slowly from 5 Hz to 500 Hz. The valve

shall then be subjected to resonance and cycling vibration in each axis,

in conformance with the times shown in Table V. If more than 4 resonances

are encountered on any axis, the 4 most severe resonances shall be chosen

for the test. The resonant and cycling period, for each axis, shall be

divided into 3 equal parts, which are conducted at -450 F ±50 F, room

temperature and +140° F ±5° F respectively. For cycling, a logarithmid

frequency sweep rate shall be used if avaiable; otherwise, other cycling

rates of frequency change may be used. The sweep rate shall be such that

15 minutes actual vibration time is required to proceed from the lower to

higher and back to the lower extremity of frequency range in accordance

with the accelerations or double amplitudes defined in Table VI.

TABLE V

VIBRATION TEST SCHEDULE

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business