MIL-C-82629(OS)

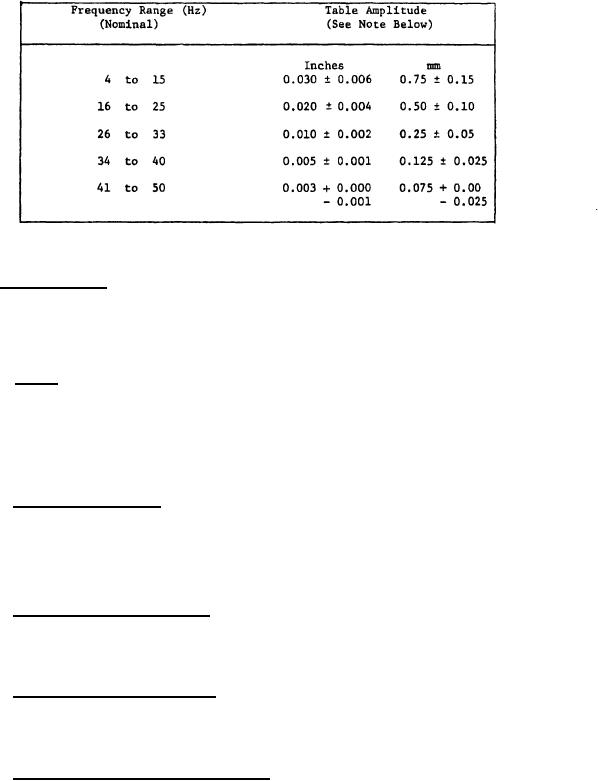

(b) Vibration Levels. The sample shall be vibrated in accordance with Table IV. The dwell

time at each integral frequency shall be not less than 5 minutes.

TABLE IV.

Vibration Levels

NOTE : All references to amplitude of vibration refer to maximum displacement of sinusoidal motion

from the position of test, or one half the total excursion,

(c) Resonance dwell. The sample shall be vibrated for not less than 2 hours at the frequency

at which the greatest resonance or discontinuities were noted. If no discontinuity or resonance

occurs, resonance dwell shall be performed at 50 Hz.

4.5.6.1.2 The above schedule shall be completed in each of the three mutually perpendicular

axes.

4.5.6.2 Shock. The cable assembly shall be mated in Torpedo Tube Cable Connector Mk 42 Mod 1

and securely mounted to a shock fixture simulating service conditions as shown in Figure 6. All

circuits shall be wired in series for the purpose of monitoring any discontinuities. The test

specimens shall be subjected to the shock test defined In MIL-S-901 for lightweight equipment.

Three shocks shall be applied parallel to each of the three principal axes as shown in Figure 6.

A total of nine shocks shall be applied. During shock, the series circuit shall be monitored

for discontinuity, using a relay chatter indicator or equivalent. Discontinuities in excess of

100 microseconds shall be considered evidence of failure.

4.5.6.3 Salt water immersion. The cable assembly, mated with Torpedo Tube Door Connector Mk

42 Mod 1, shall be subjected to a 30-day immersion test. The cable assembly shall be attached to

a fixture so that all of the plug end (tube door end) will be immersed in sea water. The cable

assembly shall be immersed for not less than 16 hours and removed for a period of not less than

8. hours. The sequence shall be repeated 30 times. No fresh water rinse will be permitted during

the 30 cycles.

4.5.6.4 Low temperature (operating). The cable assembly shall be mated to Torpedo

Tube Cable

Connector Mk 42 Mod 1 and mounted in the test chamber. The chamber temperature shall

be lowered

to +28 degrees F ±5 degrees F (-2°±3°C) and maintained for a period not less than 48

hours. At

the end of this time and while still at the test temperature, the test specimen shall

be sub-

jected to the tests of 4.5.5.2, 4,5.5.3, and 4.5.2.

4.5.6.5 High temperature (operating). The cable assembly shall be mated to Torpedo Tube

Cable Connector Mk 42 Mod 1 and mounted in the test chamber. The chamber temperature shall be

raised to 130 degrees F ±5 degrees F (54°±3°C) and maintained for a period not less than 48 hours.

At the end of this time and while still at the test temperature, the test specimen shall be

subjected to the tests of 4.5.2, 4.5.5.2, and 4.5.5.3.

4.5.6.6 Temperature and humidity (operating). The test unit shall consist of the mated assem-

bly of the "B" torpedo control cable Mk 7, one cable connector Mk 42 Mod 1, and one "A" cable

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business