MIL-C-82631(OS)

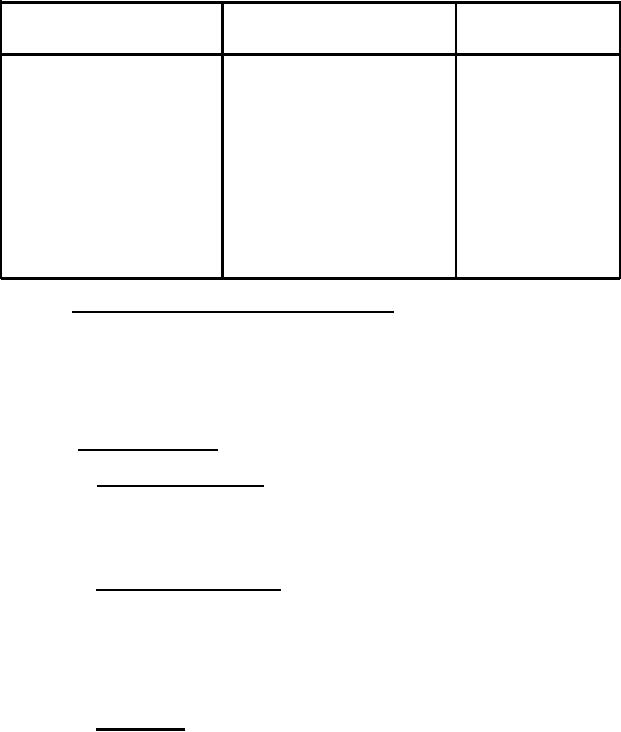

TABLE III.

INDIVIDUAL TESTS

Requirement

Method

Examination or Test

Paragraph

Paragraph

Examination of Product

3.2, 3.5, 3.6, 3.10

4.5.1

Insulation Resistance

3.8.2

4.5.3.2

Hydrostatic Pressure

3.9.1

4.5.4.1

Connector Mating and

3.7.1

4.5.2

Unmating Force

Contact, Conductor

3.8.4

4.5.3.4

Resistance

4.5.2 Connector mating and unmating force. The connector assembly

shall be mounted in a movable holding device capable of measuring force

in both a push and pull direction. Each mating cable assembly tube door

plug, or equal, shall be engaged and disengaged to the mating connector

by hand as in service use. The force required to engage and disengage

the units shall be not greater than 50 pounds with the "A" Type cable and

60 pounds with the "B" Type cable. See Figure 1.

4.5.3

Electrical tests

4.5.3.1 Dielectric strength. A voltage of 1000 volts ac shall be applied

between two points, one point being each circuit in turn, the other point

being all the remaining circuits and the shell tied together to ground.

The potential shall be applied for one minute. There shall be no indica-

tion of arcing during the test.

4.5.3.2 Insulation resistance. A 500-700 volt dc potential shall be

applied between two points, one being each circuit in turn, the other being

all remaining circuits and the shell connected together to ground. The

potential shall be applied for 2 minutes maximum or until a stable reading

is attained. The instrumentation shall be capable of detecting a leakage

current of 10 microampere or less. The cable connector shall meet the

requirements of 3.8.2.

4.5.3.3 Continuity. Each circuit shall be probed with a 6-12 volt dc

buzzer, or equivalent, for continuity. There shall be no evidence of dis-

continuity, to meet the requirements of 3.8.3.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business