MIL-C-82630 (OS)

3 REQUIREMENTS

3.1 Description. The multiconductor cables covered by this specification are extra flexible,

insulated, concentric control cables having an abrasive-resistant jacket with the external and

wire bundle diameters held to close tolerances. The Type I cable is suitable for continuous ser-

vice on board submarines while the Type II cable is suitable for continuous service at submarine

operating depth pressures.

3,2 General. Electric cable shall be of the design shown herein and shall conform to the re-

quirements of this specification and the contract or order.

3.2.1 Preproduction sample. Unless otherwise specified in the contract or order (see 6.2),

a preproduction sample of electric cable is required. The sample shall be manufactured using

the methods and procedures proposed for the production lot. This sample will be tested as

specified in 4,4.2 and is for the purpose of determining, prior to starting production, that the

manufacturer's production process will produce cables that will meet the requirements of this

specification.

3.2.2 Manufactured length. Unless otherwise specified in the contract or order, the manu-

factured length shall consist of any one single length of cable to which the impervious jacket

was applied in one length,

3.2.3 Conflicts. In the event of conflict between this specification and documents invoked

herein, the requirements of this specification shall apply.

3.3 Design and construction

3.3.1 Materials. All materials used in construction of the cable shall be of a quality and

form which will assure compliance with the requirements of this specification and applicable

drawings.

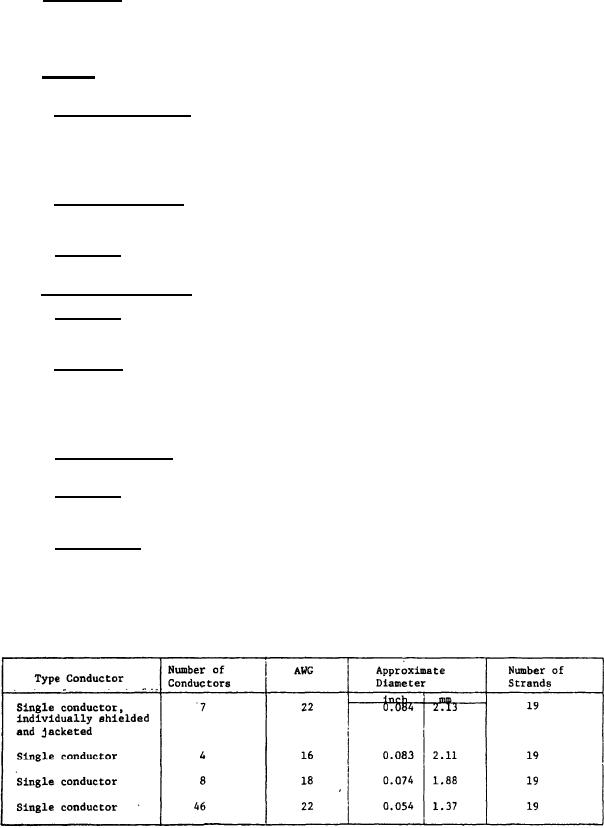

3.3.2 Conductors. All conductors shall conform to MIL-W-16878, Type E, Teflon insulated.

The conductors shell be stranded, and the number, shielding, and size shall be in accordance

with Table I for Type I cables and Table II for Type II cables. The wire insulation shall be

color coded, but only to the extent that each size, including the shielded conductors, shall

be of a different color. Individual conductors shall lie flat in their respective lay and

not cross with conductors in that or other lays.

3.3.3 Cable wire bundle. The cable shall embody 65-conductors , as specified in Tables I and

II and Figures 1 and 2, and in the contract or order. See 6.2.1.

3.3.4 Cable lay. The cable shall have a concentric contrahelical lay with a pitch of 4 to

6 inches (100 to 150 mm) in the outer layer and decreasing layer by layer toward the core as

necessary to provide cable flexibility. See 6.3.

3.3.5 Cable sheath. A sheath of tough resilient , abrasion resistant, polychloroprene shall

be applied concentrically over the conductor assembly. The sheath shall be homogeneous in

character, free from porosity, and of a quality typical of best manufacturing procedures and

shall conform to MIL-R-6855, Class 2, Grade 60. In addition, the material used shall be free

of residual release or other agents and be suitable for vulcanizing with neoprene in accordance

with MIL-STD-417, Grade SC-420.

TABLE I

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business